In March 2025, Shenzhen Guanghua Weiye Co., LTD. (brand "eSUN Yisheng") and Southwest Petroleum University officially signed an agreement on "Research on Rheological characteristics and Degradation Mechanism of degradable Hole Cleaning System".

eSUN has a deep accumulation in the research and development and application of polymer materials. Eplug degradable polymer materials developed by ESUN have played an important role in the production of oil and gas fields. At present, the company has launched fiber, particle, powder, knot, ball and other forms of products to meet the needs of different application scenarios. At the same time, the company's lactic acid and lactate products also have more mature application cases in the field of oil and gas exploitation.

The advantages of polylactic acid fiber materials in the field of hole cleaning mainly include the following three points:

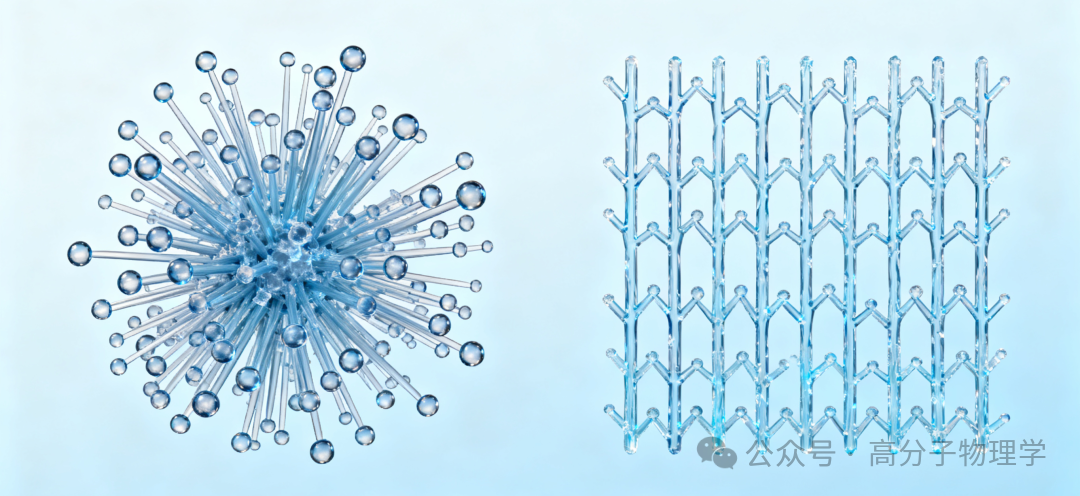

Physical adsorption and winding:

Polylactic acid fiber has large specific surface area and certain flexibility. In the borehole, the fiber can be in contact with impurities such as cuttings and drilling cuttings and adhere to its surface through physical adsorption. At the same time, the fibers will also intertwine with each other, wrapping impurity particles in them, forming larger floc or aggregate. These flocs, or aggregates, are larger than individual impurity particles and are more easily carried to the surface by drilling fluids to clean the hole.

Improve drilling fluid performance:

Polylactic acid fiber can be added as an additive to drilling fluids. It can increase the viscosity and shear force of drilling fluid and improve the rock-carrying capacity of drilling fluid. When drilling fluid circulates, drilling fluid with the right viscosity and shear force can more effectively suspend impurities such as cuttings and drill cuttings and carry them upward to the surface. In addition, polylactic acid fiber can also improve the rheology of drilling fluid, make the flow of drilling fluid in the hole more stable, reduce turbulence and eddy current phenomenon, avoid the accumulation of rock debris in the local area of the hole, and help to keep the hole clean.

Biodegradability:

Polylactic acid fiber is a biodegradable material. In the borehole environment, polylactic acid fibers are gradually broken down by microorganisms over time. This characteristic allows polylactic acid fiber to complete the wellbore cleaning task without remaining in the wellbore like some traditional cleaning materials, thus avoiding the possible adverse impact on subsequent oil and gas production operations and reducing environmental pollution.

The innovative cooperation project between eSUN and Southwest Petroleum University is a model of deep integration of industry, university and research, a positive practice of the concept of green energy development, and also marks an important step in the application of degradable materials in the petroleum industry.