On December 16, 2024, the Council of the European Union officially adopted the far-reaching "Packaging and Packaging Waste Regulation" (PPWR for short), which was published and came into effect in the Official Journal of the European Union on January 22, 2025. The implementation of this regulation marks an important step for the European Union in the fields of sustainable development and circular economy, aiming to fundamentally change the development model of the packaging industry and promote the transformation of packaging products towards recyclable and renewable directions.

-1-

Overview and Objectives of relevant regulations

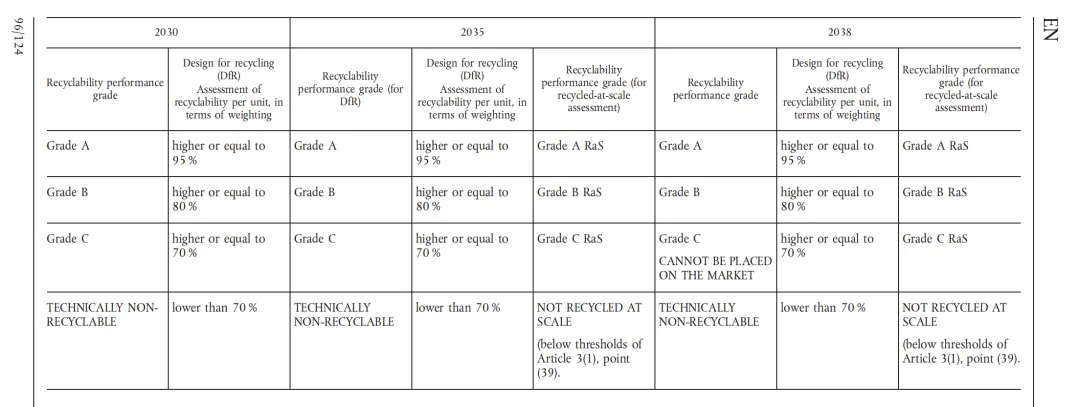

The core objective of the PPWR regulation is to ensure that by 2030, all packaging is designed to be recyclable in an economically viable manner. This means that packaging should not only be easy to classify and recycle, but also be recyclable on a large scale. To achieve this goal, the regulations have put forward a series of strict design requirements and timetables, setting clear sustainable development standards for the packaging industry.

From January 1, 2030, all packaging must comply with the Design for Recycling standard. Only packaging that reaches grade A, B or C (with a recycling rate of at least 70%) is allowed to be sold on the market.

Starting from January 1, 2038, the recyclable and renewable standards for packaging will be further raised, and it must reach at least Grade B before being put on the market.

These regulations will prompt the packaging industry to carry out large-scale technological innovation and design reforms to meet higher requirements for recyclability and regeneration.

-2-

Recyclable and renewable design parameters

The PPWR regulation emphasizes the importance of recyclable and renewable design. The design of the packaging, including all its components, must ensure recyclability and be capable of being effectively processed through verified collection, classification and recycling processes. To achieve this goal, the regulations have put forward a number of design parameters, which have a significant impact on the recyclability of packaging.

01 Additives

Substances added to materials to endow them with specific properties. Additives in packaging containers may lead to the misclassification of packaging materials during the sorting process and contaminate the obtained recycled materials.

02 Label

The coverage rate of labels will affect the efficiency of the sorting process. The type of material used to make labels and the type of glue or adhesive will also affect the quality of recycled materials.

03 Sets of standards

The coverage rate of the sleeve label on the main body of the packaging affects the possibility of sorting. In addition, the use of sleeve labels will affect their ability to be separated from the main body of the packaging. The materials used to make the sleeves will affect the sorting and recyclability of the packaging.

04 Seals and other small packaging components

Seals are used to close or seal packaging and come in various types, such as valves, rigid or flexible components (including tamper-proof shrink wrap, linings, caps, covers, etc.). The sealing material used will affect the sorting property. If the seal is not firm, it will increase the generation of garbage. Small packaging components attached to the main body of the packaging can affect the separability and recyclability of the packaging, and these components may be lost during the classification and recycling process.

05 Adhesive

The adhesive should be easy to separate during the recycling process. The presence of adhesive residues on the packaging may affect processing or be disposed of by the end user in a way that reduces the quality (purity) of recycled materials, and may also affect sorting efficiency. Washable adhesives can ensure separation from the main packaging body, avoiding adhesive residues in recycled materials.

06 Color

The substance that gives color to packaging materials. Severely stained materials in paper or plastic may cause sorting problems and reduce the quality of recycled materials.

07 Materials

Priority should be given to single materials or material combinations that are easy to separate and can ensure a high yield of recycled materials.

08 Barrier/Coating

Adding materials or substances can endow barrier properties (barrier) or be applied to the surface to provide other properties (coating). Barriers or coatings in packaging can make recycling more difficult, so a combination that can ensure a high yield of recycled materials should be chosen.

09 Ink and Paint/Printing/Coding

Ink and paint are mixtures of colorants and other substances, which are applied to materials through printing or coating processes (ink) or protective coatings made of resins or cellulose esters or both (paint dissolved in volatile solvents). Coding is directly applied to the printing of sales packaging for batch coding and other information and brand display. The use of ink containing specific substances will hinder recycling because these packaging units may not be recyclable. When printing ink is released, it will pollute the recycling flow through washing water. Unreleased printing ink will damage the transparency of the recycling flow.

10. Product residue/Easy to empty

The residues of the contents of the package will affect the sortability and recyclability of the package. The container design should facilitate the complete emptening of the contents, and during handling, it should be ensured that it is in a completely drained state.

11. Easy to disassemble

The packaging design should help to separate different components into different logistics, avoiding the components being firmly connected to each other, so as not to affect sorting and recycling.

-3-

Economic incentives and Producer Responsibility

To promote the implementation of recyclable design, the PPWR regulation has introduced an economic incentive mechanism linked to recyclable design. Specifically, the regulations propose to adjust and expand the producer Responsibility (EPR) expenses to encourage more sustainable packaging design. The adjustment of EPR fees will be based on the recyclability performance level of packaging, thereby providing clear incentives for economic operators to adopt more environmentally friendly packaging solutions.

This mechanism will help improve the functions of the internal market, while ensuring the consistency of economic incentives among different member states and avoiding managerial uncertainties for economic operators. In this way, regulations not only promote technological innovation but also facilitate the sustainable transformation of the entire packaging industry.

Although the PPWR regulations set strict recyclability standards, certain specific types of packaging can be exempted. For instance, the packaging of infant formula food, special medical purpose food, etc. can enjoy exemptions. In addition, "innovative packaging" can also be exempted for a limited period after prior notice to the competent authorities.

-4-

China's recyclable and renewable design standards

Recyclable and renewable design has become one of the core means to control plastic pollution. At present, relevant state departments have fully launched the research on the comprehensive utilization of industrial resources during the "15th Five-Year Plan" period. It is expected that "green design" will become the core concept and key focus of plastic pollution control during the "15th Five-Year Plan" period. As an important component of "green design", the results of the standard development for recyclable and renewable design will be directly incorporated into the national policy system, providing clear direction guidance and regulatory basis for the development of the plastic products industry.