Fire, this ruthless killer, constantly threatens people's lives and property safety. According to the data released by the National Fire and Rescue Bureau on January 24, 2025, in 2024, the national fire and rescue teams received a total of 908,000 fire reports, resulting in 2,001 deaths, 2,665 injuries, and direct property losses of 7.74 billion yuan. On average, there are 2,488 fires every day and one person loses their life in a fire every 3.7 hours. Behind these cold figures are countless broken families and irreparable losses. In terms of the distribution of fires, there were 350,000 fires in urban areas, accounting for 38.6%, while there were 534,000 fires in rural areas, accounting for 58.8%. The proportion of fires in rural areas was relatively large. Residential fires are the most common. Among 391,000 fires in buildings and structures, 309,000 were in residential areas, accounting for 79%. The period from 10 a.m. to 8 p.m. is the peak time for fires throughout the day, accounting for 61.4% of the total number of fires. However, although the number of fires from 0 a.m. to 6 a.m. only accounts for 10.3% of the total number of fires, the death toll accounts for 31.3%. The fatality rate of fires at night is even higher.

Among the casualties caused by fires, there is a cruel fact: most people are not directly consumed by the raging flames, but are harmed by the toxic and harmful gases produced by the combustion of traditional petroleum-based materials. Common traditional materials such as polyester and polypropylene are widely used in home textiles, architectural decoration and other fields. Once exposed to fire, they burn rapidly, releasing a large amount of highly toxic gases such as carbon monoxide, hydrogen cyanide and benzene.

The affinity of carbon monoxide for human hemoglobin is 200 to 300 times higher than that of oxygen. Once inhaled, it will quickly combine with hemoglobin, causing hypoxia and suffocation in the human body. Hydrogen cyanide is a lethal poison. It can make a person fall into a coma in just a few dozen seconds and cause death in a short period of time. According to statistics, the number of deaths caused by inhaling toxic gases in fires accounts for more than 80% of the total deaths.

Polylactic acid fiber: A new flame retardant star makes its debut

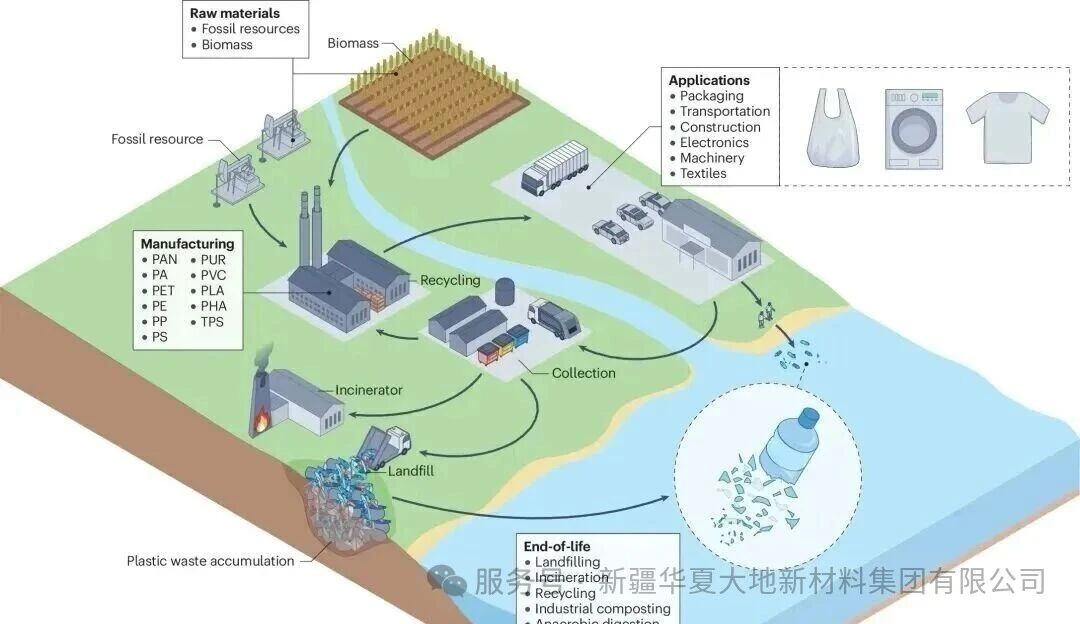

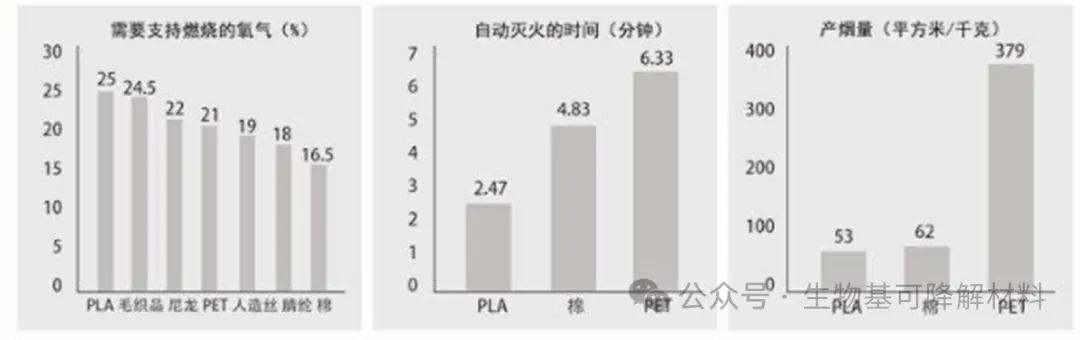

Under such a severe situation, polylactic acid fiber, as a new type of material, has become a new hope in the field of home safety with its outstanding flame-retardant performance and environmental protection characteristics. Polylactic acid fiber, also known as PLA fiber, is made from renewable plant resources such as corn and sugarcane. It shows a performance that is completely different from traditional materials when burning: it is difficult to ignite and burn, and produces almost no black smoke. When exposed to a fire source, polylactic acid fibers do not ignite as quickly as traditional fibers. Instead, there is a certain delay. Even during the burning process, the flame is relatively small, and it can extinguish itself relatively quickly after the fire source is removed. The limiting oxygen index of polylactic acid is 25, which is at a relatively high level. In contrast, the limiting oxygen index of ordinary synthetic fibers is often lower, generally around 20, and they are classified as flammable materials.

Unveiling Characteristics: Why Is It Difficult to Burn and Smokeless?

Unique chemical structure

The molecular structure of polylactic acid fibers contains a large number of ester groups (-COO-). When heated, the ester group decomposes and absorbs a large amount of heat, lowering the fiber temperature and delaying combustion. Meanwhile, the decomposition products will form a dense carbonized layer on the surface of the fibers, like a strong armor, isolating the contact between oxygen and the fibers and preventing the continuous combustion.

Moderate thermal stability

Polylactic acid fibers have relatively high thermal stability, with a decomposition temperature ranging from 200℃ to 230℃. Under normal combustion conditions, polylactic acid fibers need to absorb sufficient heat to reach the decomposition temperature before burning. Compared with some traditional fibers with low melting points and high flammability, polylactic acid fibers are more difficult to ignite.

Low carbon content and full oxidation

Polylactic acid fibers have a relatively low carbon content, and hydrogen exists in the form of C-H bonds. When burning, it can be fully oxidized and is less likely to produce incompletely burned carbon particles. Therefore, there is almost no black smoke during the combustion process, which greatly reduces the harm of thick smoke to the human respiratory tract in fires.

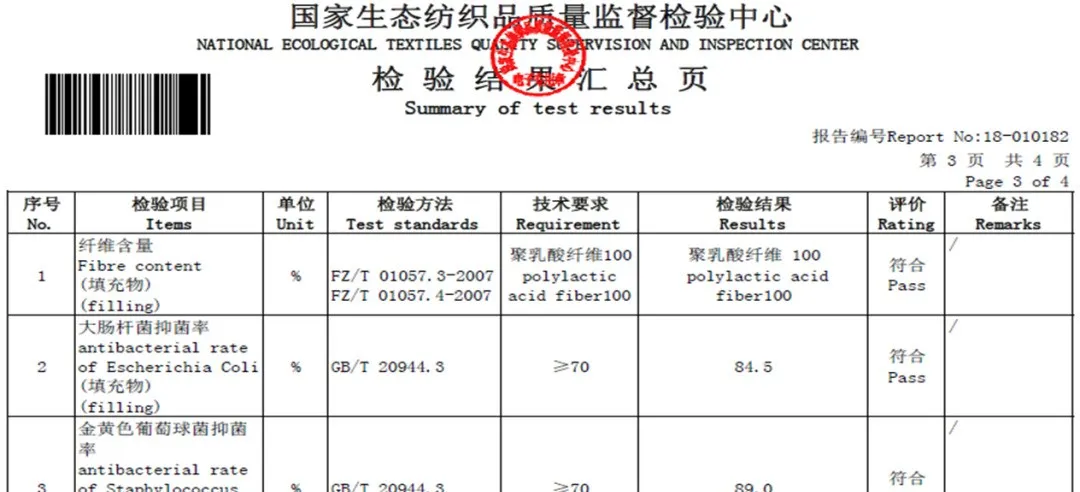

Home application: Feasibility and advantages are fully demonstrated

Bedding: Polylactic acid fiber is soft, skin-friendly and breathable, providing a comfortable sleep experience. Natural antibacterial and anti-mite properties keep the bed clean and healthy, reducing the breeding of bacteria and mites. The quilts, four-piece sets and other items made not only meet the comfort requirements but also ensure sleep safety and reduce the risk of fire. The antibacterial rate of polylactic acid fibers against Candida albicans, Escherichia coli and Staphylococcus aureus can reach over 80%, reaching the AAA-level antibacterial standard.

Curtains: Curtains are an important part of home decoration. Polylactic acid fiber curtains not only come in a variety of styles and are elegant and generous, but also have the characteristics of being difficult to burn and ignite. When a fire breaks out, it can delay the spread of the fire, reduce the production of toxic smoke, and buy precious time for people to escape and for fire rescue. Its burning speed is about 30% lower than that of traditional chemical fiber curtains, and the smoke emission is reduced by about 40%.

Carpet: Polylactic acid fiber carpet offers a comfortable foot feel and good warmth retention. Its excellent flame retardant performance makes the carpet less likely to catch fire when exposed to open flames. Even if it does burn, it will not release a large amount of toxic gases, enhancing the safety of the indoor space. Meanwhile, it is also wear-resistant, easy to clean and highly practical.

Furniture filling: In terms of furniture fillers such as sofas and throw pillows, polylactic acid fibers also perform well. Traditional foam fillers are flammable and produce a large amount of toxic gases when burning, while polylactic acid fiber fillers are much safer. They can effectively reduce the risk of furniture in fires and provide a safer usage environment for families.

Industry Practice: Brand leads development

Many enterprises in the market have keenly identified the advantages of polylactic acid fibers and actively engaged in their production and application. Yomi Baby, as a Sino-Korean joint venture maternal and infant brand under ndo Corporation of South Korea, applies polylactic acid fibers to textile fabric products, covering a wide range of products such as baby products, children's clothing, parent-child home wear, and bedding. This brand adheres to the concepts of green, healthy and comfortable. Relying on the natural antibacterial, safe and environmentally friendly properties of polylactic acid fibers, it has created comfortable and safe products for babies, earning the trust of many parents.

Xtep has also launched 100% polylactic acid trench coats and running shoes with a bio-based content of over 20%. Its polylactic acid trench coat not only has excellent flame retardant performance, but also strikes a balance between functionality and fashion sense, meeting consumers' dual demands for safety and aesthetics in outdoor sportswear, and demonstrating the application potential of polylactic acid fibers in the clothing field.

Polylactic acid fibers have shown great application potential in the home textile field due to their characteristics of being difficult to burn and smokeless when burning. It can not only effectively reduce the risk of fire and minimize casualties, but also conform to the concepts of environmental protection and sustainable development. With technological advancement and market promotion, it is believed that polylactic acid fibers will play a greater role in future home life and build a solid safety line for us.